MODIFIED ATMOSPHERE PACKAGING

Experience the United Bags Advantage for FIBC (Bulk Bags, Super Sacks) and small bags across a multitude of industries.

The Six Keys that Make Up Our Modified Atmosphere System

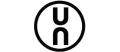

1. Liner Material

The liner in a FIBC depends on the product and circumstances during storage and transport. The liner is built with up to nine different layers of various materials, to create a barrier against moisture and keep ultra-low oxygen levels and the flavor intact. The liners are produced to very stringent quality conditions and up to ISO standards.

We use a wide range of barrier foils for moisture levels, oxygen and flavor for our liners such as conductive, aluminum, anti-static, dissipative, metalized OPP, EVOH and PA liners.

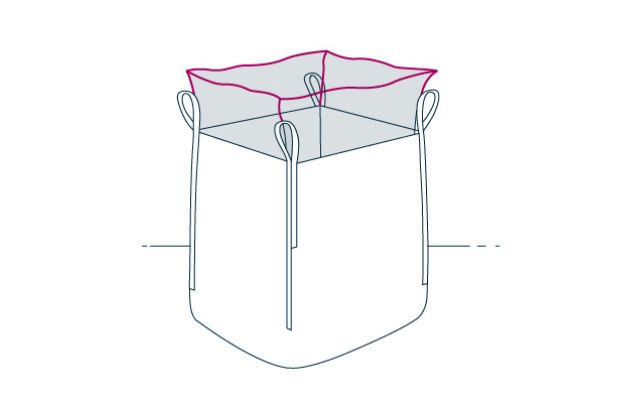

2. MA Powerqube & Powertube Liners

A FIBC with a form stabilized liner system inside ensures a square and optimal shape after filling, during storage and transport. The pre-shaped liner is completely welded in the top and bottom and if required in the side seams.

- 15% on transport volumes can be saved with form stable FIBC Liners.

- 15-20% less material used for the production of a liner

- Modular produced

- Unique controlled sealing technique

- High load ability

- ISO production facility

3. MA Powerqube & MA Powertube Liners

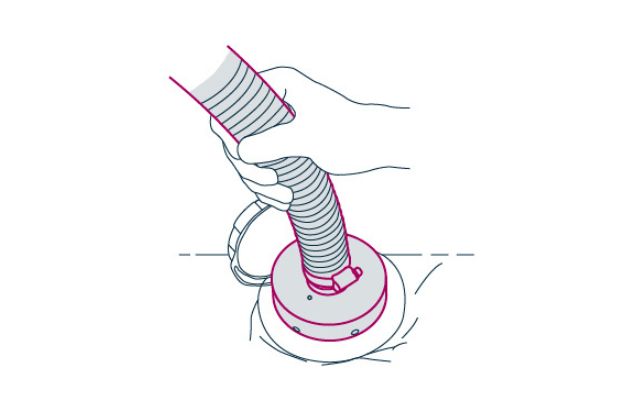

The valve is attached to the liner of the FIBC and gives a secure airtight connection between the environment inside the bag and the Vacuum and Gas Injection Machine. Each valve is equipped with a filter, which ensures that products stay in the liner and gasses can move openly in and out of the liner.

A reliable valve is the key to a successful preservation process! The benefits are:

- Fool-proof connection

- Fast processing times

- Single or multiple flushes

- Lower energy needed

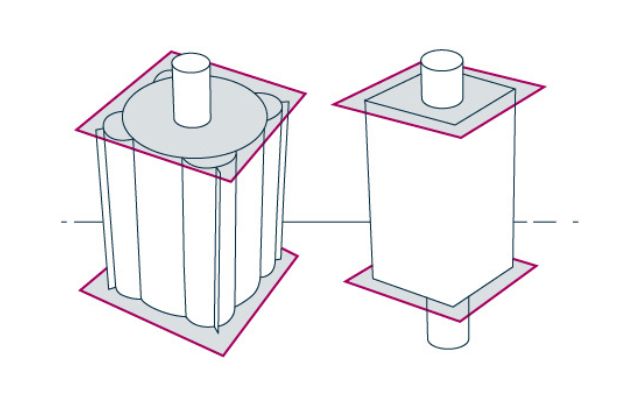

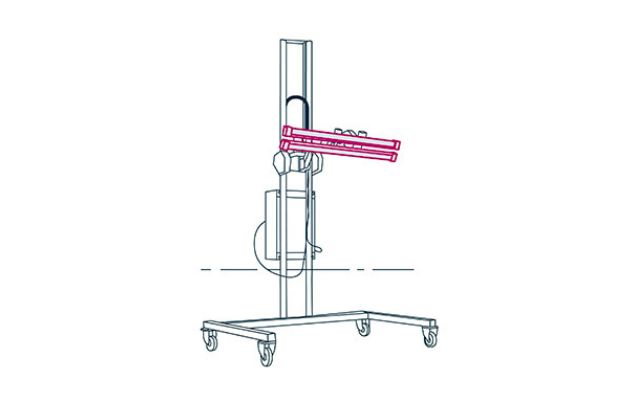

4. Automatic Spout Sealer

A machine that seals the filling spout of a FIBC so that the product content is secured. Depending on the size and position of the FIBC, the machine can be adjusted to its correct height and width of the filling spout. After positioning the filling spout into the sealing machine, the sealing process is fully automatic.

- Reliable and safe way of sealing

- Constant quality and performance

- Mobile moveable machine

- Small footprint and setup

5. Vacuum & Gas Injection Machine

Modified Atmosphere is used as a way of natural fumigation, using ultra-low oxygen levels (ULO) in combination with Nitrogen or Carbon Dioxide to protect products from infestation by insects and extending the shelf life of your products.

- Vacuum & gas flushing including pressure control & leak test

- Short process times

- Completely customizable process

- Highest class approved machine

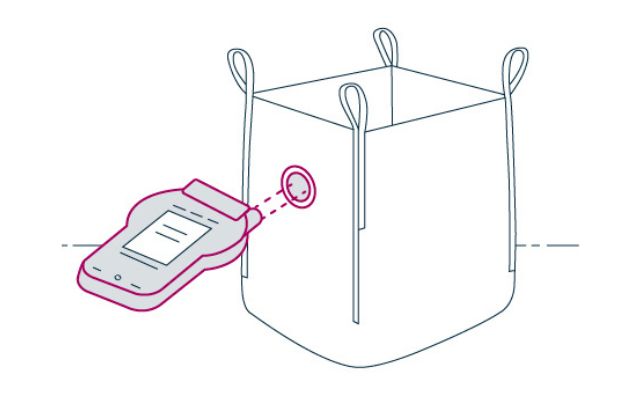

6. Modified Atmosphere Control

There are two different ways to measure and control the Oxygen level inside the bags.

- The traditional and very reliable way to measure oxygen and gas levels is the evasive method which uses a needle tool that pierces into the sealed liner bag.

- The new way is a totally non-invasive technique called Sensor Spot Technology that does not require piercing a needle into the liner bag.

Discover Trusted Bulk Packaging Solutions with United Bags

United Bags is your premier partner for high-quality, customizable bulk packaging solutions. Our commitment to excellence and customer satisfaction ensures that you receive the best products tailored to your specific needs. Whether you're looking for durable, efficient, or eco-friendly options, our diverse range of products and services cater to various industries. Connect with us to explore our offerings and elevate your custom packaging with one of our experienced sales team members!