Order SUPER SACK® Bulk Bags by Size and Specifications

Types of SUPER SACK® FIBC Bulk Bags

SUPER SACK® FIBC bags range from Type A to Type D, each ideal for a specific application. The Type of FIBC typically denotes how conductive the material used to make it is and whether it can be used to transport or store combustible or flammable materials, with A being the least suited and D being the most suited.

Type A

Type A SUPER SACK® FIBC bags are manufactured using plain woven polypropylene and other non-conductive fabrics. They do not provide static protection and should not be used with combustible materials or in flammable atmospheres.

Type B

Type B SUPER SACK® FIBC bags are made from materials with a low breakdown voltage (less than 4KV) that prevent propagating brush discharges (PBD). Although they can prevent PBD, they are not antistatic because they do not dissipate electrostatic charges. They can be used around minor combustible dust with an MIE greater than 3mJ, provided flammable vapors or gases are absent.

Type C

Type C SUPER SACK® FIBC bags, or groundable FIBCs, are made from non-conductive polypropylene fabrics interwoven with conductive threads sewn in a grid pattern. These bags must be grounded during filling and discharge. They are suitable for transporting flammable powders and can be used in the presence of flammable vapors, gases, dust, or solvents.

Type D

Type D SUPER SACK® FIBC bas, also known as Antistatic FIBCs, are inherently antistatic and do not require grounding to be safe. They are made from non-conductive polypropylene fabrics interwoven with conductive threads sewn in a grid pattern. These bags do not need to be grounded and can safely transport flammable powders. They can also be used in the presence of flammable vapors, gases, dust, or solvents.

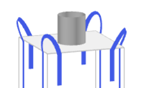

Four Point

Each corner has its own single loop, sewn into the seams of the bag.

Cross Corner

Each corner has a loop. Each side of the loop is sewn into one side of the bag.

Double Loops

Each corner has two connected loops sewn into the seams of the bag.

Stevedore Strap

Each side of the bag has a strap that is connected to two corners.

Tunnel Loops

Each side of the bag has a sleeve lift that spans the entire side, corner to corner.

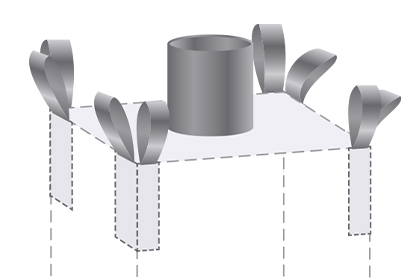

Spout

Cylindrical spout sewn on the top panel. Size can be altered by your filling equipment.

Duffle

Opening as wide as the bag’s width and depth and acts as an extension of the bag.

Open

No closing material included on the top panel of the bag.

Spout

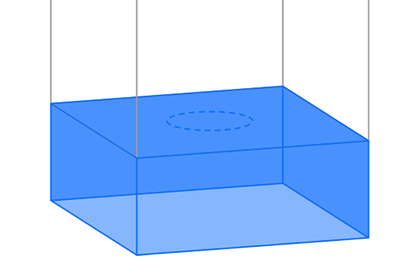

Cylindrical spout sewn on the bottom panel. Size can be altered by your filling equipment.

Flat Bottom

Standard bottom panel with no means of discharge. Material released by cutting the panel.

Full Bottom Discharge

The bottom panel is tied to the side of the bag to allow product to be released.

Porthole

The liner inside the bottom panel is cut to allow product to be released.

Tubular Lay-Flat

Cylindrical liner with no spouts that is open at the top and sealed at the bottom.

Form Fit

Made to exact FIBC specifications that can heat seal the top and bottom spouts for protection.

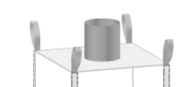

Baffled

Maintains the cubic form of the bag for improved storage and less bulging.

Aluminum Foil Liner

Superior protection against oxygen, moisture, and UV light.

Conductive Liners

Available in L1, L2, or L3 and reduces static build-up during transportation.

Specialty SUPER SACK® FIBC Bags

SUPER SACK® FIBC bags can suit various needs depending on industry requirements, governmental regulations, and operational efficiencies. Most commonly, our clients request three specific types of specialty FIBC bulk bags designed to accommodate the exact nature of the job they have in mind.

Food and Pharma Grade FIBCs

Our food and pharma-grade FIBC bags are manufactured with meticulous attention to quality and safety. We use 100% virgin raw materials, FDA-approved lubricants, and adhere to strict certification standards like AIB, BRC, GMP, HACCP, and ISO 9001. Each bag undergoes ultrasonic cutting, external stitching with twisted PP yarn, thorough inspections including metal detection, and is securely packed to prevent contamination.

FIBC Baffle Bags

Baffle bags are designed to improve squareness, appearance, and load stability, optimizing storage and shipping space. These bags can hold more volume and stretch less than standard FIBCs. Standard baffle bags feature fabric pieces sewn across each corner to maintain a cubic form and reduce bulging. Net baffle bags have mesh sewn across each corner, ensuring equal distribution of fill product and a faster filling process.

UN-Certified Bulk Bags

Our UN bags are designed to meet the stringent United Nations requirements for transporting and storing hazardous materials. They undergo seven primary tests as part of the certification process, ensuring maximum safety and durability. We offer various types, including 13H1, 13H2, 13H3, and 13H4, all manufactured at a 6:1 Safety Factor. Our experienced sales team is certified to assist you in designing the perfect UN bag for your needs.

- Manufacturing plants are audited by United Bags Quality Control Team.

- We are in partnership with the Customs Trade Partner Against Terrorism (C-TPAT) program.

- Bags are BRC, AIB, SQF, FSS 22000 and ISO 21898 certified with bags being produced meeting the Global Food Safety Initiative (GFSI) standards.

- Our quality control and experienced sales teams have the ability to test the safe working load of FIBCs in our innovation lab.

- Our Research & Development team can help you with your one-of-a kind designs.

- Our experienced sales team can manage your inventory (VMI) for just in time delivery with our advanced technology.

- We are UN and UL certified to ensure that your bags are meeting safety requirements.

Our innovation lab will test your current FIBC bag for FREE to ensure it meets quality standards.

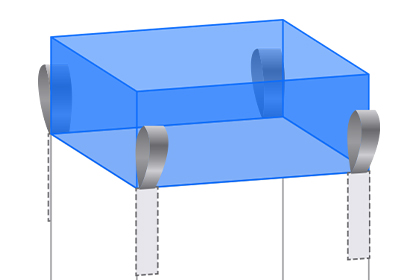

A Flexible Intermediate Bulk Container (FIBC) is a bag made out of woven polypropylene used to store and/or transport dry products. Dimensions can vary and typically hold anywhere from 2,000–4,000 lbs. Once the bags are filled, they are placed on pallets and forklifts use the corner lift loops to transport.

Bulk Bags, Big Bags, SUPER SACK® FIBC, and Totes

100% virgin polypropylene or up to 30% recycled polypropylene for sustainability. FIBCs can also be made from 100% recycled polyethylene terephthalate (rPET).

FIBCs come in many different sizes and styles and are customized for your product and are designed to fit squarely on a pallet.

FIBCs can be lifted with a forklift by either their loops or on a pallet.

You would need to lift the FIBC under a discharge area and open the discharge spout and let gravity do the work.

You will need:

- Bulk density of your product

- Type of filling equipment you will be using

- How much weight you plan to put in it

- The end users discharge equipment they will be using

A food-grade bag’s fabric is FDA approved for use in food packaging. Special steps are taken during the manufacturing process to ensure its safety, such as AIB, BRC, ISO, and SQF certifications.

Circular

- This style is made from fabric woven on a circular loom. The process eliminates the vertical seams on each side of the bag. The tubular body design is ideal to use without a liner and is ideal for fine products.

4-Panel

- It requires seams along four separate pieces of fabric sewn together to create a 4-Panel bag. This style is excellent for a variety of applications.

U-Panel

- This style takes two pieces of woven polypropylene material which forms the U shape. This is a cost-effective bag as it results in less stitching and waste. It is ideal for construction and a variety of industries.

Type A

- Are manufactured using plain woven polypropylene and other non-conductive fabrics

- Does not give static protection and should not be used with a combustible material

- Do not use near a flammable atmosphere

Type B

- Are made from materials that have a low breakdown voltage (less than 4KV) that halts propagating brush discharges (PBD).

- Although they can prevent PBD (propagating brush discharges), they are not considered anti-static bulk bags because they do not dispel an electrostatic charge.

- They can be used in the presence of minor combustible dust with MIE more than 3mj, provided flammable vapors or gasses are absent.

Type C

- The non-conductive polypropylene fabrics used to manufacture conductive Type C FIBCs are interwoven with conductive thread and sewn in a grid pattern

- The safe use of Type C bulk bags must be grounded throughout filling and discharge

- Flammable powders can be transported

- Can be used in the presence of flammable vapors, gasses, dust, or solvents around the bag

Type D

- Sometimes called Antistatic FIBCs are inherently antistatic and do not require grounding to be safe

- The non-conductive polypropylene fabrics are interwoven with conducting threads and sewn in a grid pattern

- Bag does not need to be grounded

- Flammable powders can be transported

- Can be used in the presence of flammable vapors, gasses, dust, or solvents around the bag

FIBCs can be used more than once if you have a multi-trip bag with a 6:1 Safety Factor (SF).

Discover Trusted Bulk Packaging Solutions with United Bags

United Bags is your premier partner for high-quality, customizable bulk packaging solutions. Our commitment to excellence and customer satisfaction ensures that you receive the best products tailored to your specific needs. Whether you're looking for durable, efficient, or eco-friendly options, our diverse range of products and services cater to various industries. Connect with us to explore our offerings and elevate your custom packaging with one of our experienced sales team members!