SUSTAINABILITY

Experience the United Bags Advantage for FIBC (Bulk Bags, Super Sacks) and small bags across a multitude of industries.

- Environmental Impact Reduction: rPP FIBCs are made from 30% recycled polypropylene, which is a plastic commonly used in packaging and consumer goods. By using rPP FIBCs, companies can help reduce the amount of plastic waste in landfills and decrease greenhouse gas emissions.

- Energy Conservation: The production of rPP FIBCs requires less energy compared to the production of FIBCs made from virgin materials. The use of recycled materials reduces the need for virgin materials, which requires less energy and reduces the carbon footprint.

- Durability and Strength: rPP FIBCs are known for their durability and strength. They can withstand heavy loads, rough handling, and long periods of storage without tearing or breaking.

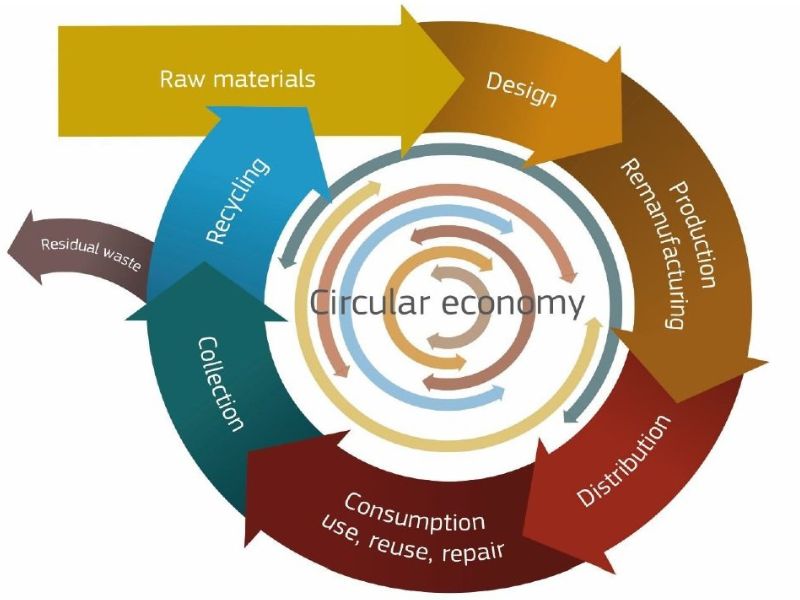

- Recycling Capabilities: rPP FIBCs can be easily recycled at the end of their useful life.

- Biodegradable Materials: FIBCs made from biodegradable materials, such as bioplastics or natural fibers, can break down naturally in the environment and reduce the amount of waste that ends up in landfills or the environment. These materials are made from renewable resources and have a lower carbon footprint compared to traditional plastic.

- Reduced Packaging: Companies can consider reducing the amount of packaging used in FIBCs by using lighter fabrics, reducing the size of the bags, or optimizing the shape of the bags to fit the product more efficiently. This reduces the amount of material used and can also reduce transportation costs and carbon emissions.

- Reusability: FIBCs can be designed for multiple uses, reducing waste and the need for frequent replacements. By using durable and high-quality materials, FIBCs can be reused multiple times, reducing the environmental impact of the packaging.

- Environmental Impact Reduction: rPET FIBCs are made from recycled polyethylene terephthalate, which is a plastic commonly used in water and soda bottles. By using rPET FIBCs, companies can help reduce the amount of plastic waste in landfills and the environment. This can have a positive impact on the environment by reducing greenhouse gas emissions and conserving natural resources.

- Energy Conservation: The production of rPET FIBCs requires less energy compared to the production of FIBCs made from virgin materials. Using more recycled materials means less virgin materials, less energy, and a smaller carbon footprint.

- High fabric strength

- Less bulging

- Higher UV protection than traditional a FIBC made from virgin PE

- High print quality

- Improved abrasion resistance

- High seam strength

- Takes higher heat

Sustainability: Protect your product from the inside out!

As awareness of environmental issues grows, food spoilage and waste management become a critical concern. The future of sustainable packaging revolves around preserving the product inside the packaging, reusability, recycling, and composting. United Bags packaging experts can help you design packaging across all bag types to reduce spoilage, reduce waste, and reduce your environmental footprint. To learn more, contact us today!

MAP FIBCs can help to save food and improve sustainability. Modified Atmosphere Packaging (MAP) works by applying a deep vacuum to the 100% airtight high-barrier liners within the external FIBC big bags. After this, the bags are gas-flushed with either nitrogen or carbon dioxide. This results in residual oxygen levels inside of the liners being <1% and an inert atmosphere.

This method is the perfect solution for protecting and storing many commodities, such as food powders, food products, nuts, dehydrated fruit, pharmaceutical API powders, grain, coffee, rice, tea, cocoa powder, chemicals, fine powders, pigments, and others.

- 2-way valve for extracting oxygen and introducing nitrogen or carbon dioxide

- Better option than a 1-way vacuum

- View each bag’s oxygen levels on your mobile device

- No need for needles to test levels, avoiding opportunities for contamination and leakage

- Can rack the bags until they are needed

- Make better decisions on which bag to use next

TELLAP pallet less big bags provide users with a low-cost alternative to a bag and wooden pallet. A TELLAP bag has two sleeves integrated into the base that hold the bag open for standard forklift tines. The sleeves allow a forklift to safely raise the bag from the base, removing the need for a pallet. Removing the pallet allows bag volume to be increased, lowering both operational and transport costs. Increasing volume in each bag can lower transport costs per metric ton by up to 10%. That’s 10% fewer bags, containers, trucks, and forklift movements — the savings apply right through your business.

- No pallet required

- Excellent stability, safety, and hygiene

- Bags can be safety stacked, reducing warehouse space requirements

- Increased payload, reduced operational and transport costs

- Dead weight reduction, as sleeves weigh only 5 lbs — some pallets weigh up to 65 lbs

- No damage or contamination from nails, splinters, or foreign objects

- ISPM 15 compliant — no fumigation or heat treatment required

- Reuse or recycle — no waste with TELLAP

BOPP and or polyethylene bags are a great sustainable option to replace valve and open mouth paper bags by using Bioresins and Bioplastics for small LDPE and HDPE (50-55 lb.) bags. Paper bags have PE liners glued in them and because of the mixture of paper and PE, these bags cannot be recycled.

- Sugarcane metabolizes and produces sucrose, which is distilled to produce ethanol.

- The ethanol goes through a dehydration process to produce ethylene.

- The last step is the ethylene being polymerized into PE.

- The product behaves like conventional plastics.

- It can be recycled like traditional PE.

- If it ends up in a landfill, the product will naturally biodegrade over time.